How to Identify Quality in Braided Rope

At Cancord, our primary focus is quality rope. Our team works continuously to improve both our products and our processes such that our customers know when they purchase from Cancord they are always getting the best possible rope at the best possible price. A quality braided rope will have a smooth, uniform appearance when new. […]

What’s Your Breaking Point?

Questions often arise surrounding the difference between the minimum breaking strength and the safe working load of a rope. The minimum breaking strength of a rope is usually the optimum strength achieved under laboratory conditions, in accordance with prescribed test procedures, on new rope, pulling at a slow, steady rate in a straight line. Real […]

Frayed Knot – What You Definitely Do Not Want to See in a Life Line

When it comes time to order a lifeline, rescue rope, or other type of safety line, quality is a primary consideration. Many applications, and jurisdictions have certifications that lifelines must adhere to. In Canada, one of the primary certifications for lifelines is CSA (Canadian Standards Association). Lifeline Certification to CSA Z259.2.5 requires rigorous testing and […]

New General Purpose Catalogue

We’re happy to announce the release of Cancord’s sleek new Industrial & General Purpose product catalogue. Download it today to learn about our new & existing products.

How do I identify a quality braided rope?

A quality braided rope will have a smooth, uniform appearance when new. When purchasing a new piece of rope, look down the length of the rope for possible quality concerns such as broken yarn filaments, looped or pulled strands, uneven yarn color, or any other irregularity. Broken Yarn Filaments most likely indicate the use of […]

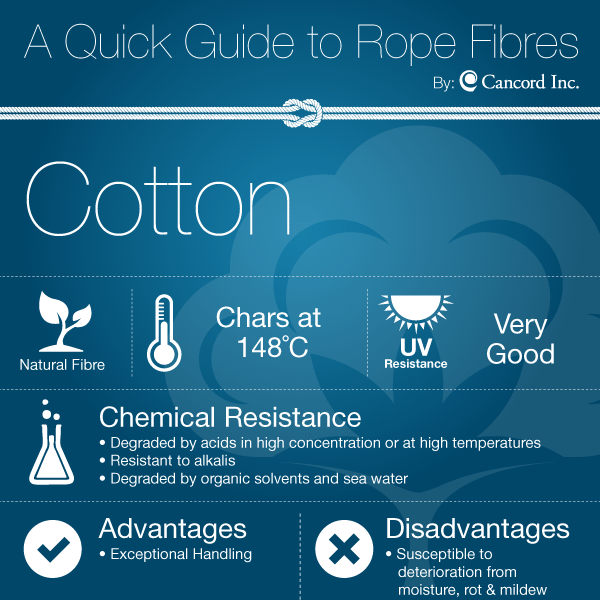

A quick guide to rope fibres

Our quick guide to rope fibres infographic offers you an at-a-glance view of all the features, advantages, and disadvantages of a variety of rope fibres that we manufacture. You can download the full infographic, or click the preview below to see it in your browser.

What are some important precautions when using rope?

You should be aware that a rope’s rated breaking strength is the optimum strength, achieved under laboratory conditions, in accordance with prescribed test procedures, on new rope, pulling at a slow, steady rate in a straight line. Real life applications normally involve many different types of forces and factors which will cause the rope to […]

Guide to Rope Construction

Twisted Ropes These ropes can be recognized by their spiral shapes. They are made by twisting together bundles of individual yarns to form strands, which are then twisted together to form the rope. Twisted ropes are easily spliced, but have inherent torque and therefore a tendency to kink up and rotate under load. Braided Ropes […]

How do I wash my rope?

All ropes, particularly those used in life critical applications should be kept clean and free of dirt, chemicals and other contaminants to prevent damage and wear that will reduce the strength, effectiveness, and durability of the rope. Where ropes have been exposed to chemicals, excessive dirt or other contaminants, we recommend discarding the rope, or […]

The Evolution of Stage Cord

Our HERCULES™ 100% Cotton Sash Cord is one of the products that we have been manufacturing the longest. It is a nice soft cord, that is easy on the hands, and knots well. It originates from a time when synthetic fibers did not exist, and so many of the ropes available commercially were manufactured from […]